Expansion tank precautions

- Current location:

The expansion tank is pre-filled with nitrogen pressure at the factory, and damage to the expansion tank may cause serious consequences. It should be handled gently during transportation, handling, installation and use. It is strictly forbidden to strike, burn or violently open barracks such as expansion tanks.

The bracket (or other device) used to mount the fixed expansion tank must have sufficient strength to withstand the weight of the entire expansion tank after filling with water.

The system connected to the expansion tank shall be equipped with safety devices (such as safety valves) to limit the system pressure and ensure that the maximum working pressure of the expansion tank is not exceeded.

The water in the expansion tank may be hot while the system is in operation, so do not touch it directly with your hands.

When the expansion tank is in stock for more than three months, it is necessary to check the nitrogen pressure of the expansion tank. If the expansion tank pressure is insufficient, it will be inflated to the specified pressure.

After pre-filling with nitrogen pressure, the expansion tank will inevitably produce slow leakage. Therefore, at least one aeration is performed every year, and the inflation gas is nitrogen. If there is no nitrogen, air can be used instead. At the same time, the nitrogen pressure in the expansion tank is affected by the external temperature, so the nitrogen pressure is detected at least every six months.

The nitrogen pre-charge pressure detection and inflation method of the expansion tank is as follows:

1. This operation and maintenance can only be carried out by qualified personnel.

2. Check that the nitrogen pressure in the expansion tank is at least every six months. Before performing this operation, make sure that the system is off, cooled, unpressurized, and that all electrical equipment has stopped working and that there is no pressure in the expansion tank (the water in the expansion tank is completely drained).

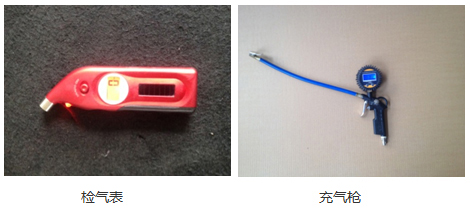

3. Unscrew the valve cover and use a gas meter to measure the nitrogen pressure in the expansion tank.

4. If inflated, use a pneumatic gun to charge the expansion tank nitrogen pressure to the standard value indicated on the label.

5. After the pressure measurement and inflation are completed, apply soapy water to the valve core to confirm that the valve core is effectively rebounded.

6. Close the valve cover and tighten.

Note: When measuring the nitrogen pressure of the expansion tank, please use a small barometer as much as possible to avoid excessive nitrogen leakage.